November 07, 2025

Troubleshooting Common Mechanical Issues in Antique Typewriters

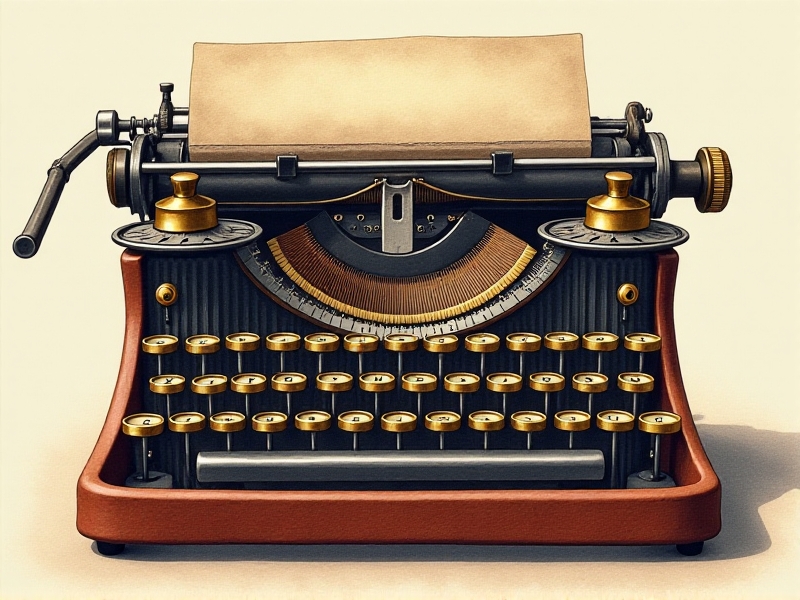

Understanding the Anatomy of an Antique Typewriter

Before diving into troubleshooting, it's essential to understand the basic components of an antique typewriter. These machines are marvels of mechanical engineering, consisting of a complex interplay of levers, springs, and gears. The key elements include the typebars, which strike the paper; the ribbon mechanism, which transfers ink; the carriage, which moves the paper; and the platen, the rubber roller that feeds the paper. Familiarizing yourself with these parts will make it easier to identify and fix issues when they arise.

Common Issues with Typebars and How to Fix Them

One of the most frequent problems with antique typewriters is malfunctioning typebars. These metal arms can become stuck, bent, or misaligned, preventing them from striking the paper correctly. To address this, start by cleaning the typebars with a soft brush and a mild solvent to remove any accumulated dirt or dried ink. If a typebar is bent, carefully use pliers to straighten it, ensuring not to apply too much force. For misaligned typebars, gently adjust their position so they strike the paper evenly. Regular maintenance can prevent these issues from recurring.

Dealing with Ribbon Feed Problems

Another common issue is the ribbon not feeding properly, which can result in faint or uneven typing. This problem often stems from a worn-out ribbon, a misaligned ribbon spool, or a faulty ribbon vibrator. First, replace the ribbon with a new one designed for your specific typewriter model. If the issue persists, check the alignment of the ribbon spools and adjust them if necessary. The ribbon vibrator, which moves the ribbon up and down, may also need cleaning or lubrication to function smoothly. Ensuring the ribbon mechanism is in good working order will improve the quality of your typing.

Addressing Carriage Movement Issues

If the carriage of your typewriter isn't moving smoothly or is getting stuck, it can be a frustrating experience. This problem is often caused by dirt, rust, or worn-out parts within the carriage mechanism. Begin by cleaning the carriage rails and gears with a soft brush and a suitable solvent. If rust is present, use a rust remover and then apply a light lubricant to the moving parts. In cases where parts are worn out, you may need to source replacements from a specialist or fabricate new parts. Regular cleaning and lubrication can keep the carriage moving freely.

Fixing Platen and Paper Feed Problems

The platen, or rubber roller, is crucial for feeding paper through the typewriter. Over time, the platen can harden, crack, or become misaligned, leading to paper feed issues. If the platen is hardened or cracked, it may need to be re-covered or replaced. For misalignment, adjust the platen's position so it feeds the paper evenly. Additionally, ensure that the paper bail, which holds the paper in place, is functioning correctly. A well-maintained platen and paper feed mechanism will ensure smooth and consistent typing.

Maintaining and Lubricating Moving Parts

Proper maintenance and lubrication are key to keeping an antique typewriter in good working condition. Over time, the moving parts can become stiff or noisy due to a lack of lubrication. Use a high-quality, light machine oil to lubricate the pivot points, gears, and other moving parts. Be cautious not to over-lubricate, as excess oil can attract dirt and cause more problems. Regular cleaning and lubrication will extend the life of your typewriter and ensure it operates smoothly.

Restoring the Appearance of Your Antique Typewriter

Beyond mechanical issues, the appearance of your antique typewriter is also important. Over time, the metal parts can tarnish, and the paint may chip or fade. To restore the appearance, start by cleaning the exterior with a gentle metal polish. For painted surfaces, touch up any chips with matching paint. If the decals are worn, consider sourcing replacements or having them professionally restored. A well-maintained typewriter not only functions better but also looks beautiful as a piece of history.

Preventative Maintenance Tips for Long-Term Care

To keep your antique typewriter in top condition, regular preventative maintenance is essential. Clean the machine after each use to remove dust and debris. Store it in a dry, temperature-controlled environment to prevent rust and other damage. Periodically check all moving parts for signs of wear and address any issues promptly. By following these preventative maintenance tips, you can ensure your typewriter remains a functional and cherished piece of history for years to come.